-

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English) -

[email protected]

[email protected]

In modern precision manufacturing, grinding machines are key equipment for the finishing of parts, directly determining the surface roughness, dimensi...

View MoreIn modern precision manufacturing, grinding is a crucial process that determines the final precision and surface quality of parts. As the core equipme...

View MoreIn modern precision manufacturing, balancing efficiency and precision has always been a core objective pursued by enterprises. With the advent of Indu...

View MoreAs an indispensable high-end equipment in modern precision machining, CNC cylindrical grinding machines play a crucial role in many industrial sectors...

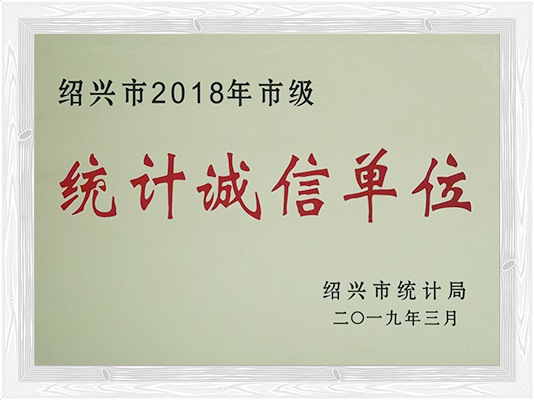

View MoreZhejiang Quanshun Machine Tool Co., Ltd. is a leading enterprise in China that focuses on the production of precision grinding machines. It integrates CNC Cylindrical Grinding Machine Manufacturers and CNC Cylindrical Grinding Machine Factory. The company not only has a large-scale machine tool production base, but also is equipped with a professional hydraulic parts production base, ensuring the quality control of the entire chain from raw materials to finished products.

CNC Cylindrical Grinding Machine is a high-precision machine tool that controls the relative movement of the workpiece and the grinding tool through the CNC system to achieve high-precision grinding of the outer surface of cylindrical parts. CNC Cylindrical Grinding Machines use two top centers as the center and grinding wheels as tools to grind cylindrical steel parts to precise concentricity. Cylindrical grinders are divided into ordinary cylindrical grinders and universal cylindrical grinders. Ordinary cylindrical grinders are mainly used to grind the outer cylindrical surface and outer conical surface of the workpiece, as well as the end face of the stepped shaft, etc.; while universal cylindrical grinders can grind the inner cylindrical surface and inner conical surface as well as the end face.

During the working process, the workpiece is mounted on the workbench and rotated by the spindle. At the same time, the grinding head performs high-precision grinding along the predetermined trajectory under the control of the CNC system. The worktable is fed through the linear guide rail of the bed, so that the workpiece and the grinding tool have relative movement, thereby completing the grinding process.

The CNC Cylindrical Grinding Machine adopts an advanced CNC system, which integrates precision sensors, high-speed processors and advanced control algorithms to achieve precise control of the grinding process. Through preset processing parameters and real-time feedback mechanisms, the CNC Cylindrical Grinding Machine can ensure that the workpiece achieves extremely high dimensional accuracy and shape accuracy during the grinding process. This high-precision processing capability makes the CNC Cylindrical Grinding Machine the preferred equipment in the field of precision manufacturing, especially in applications where strict control of tolerances and surface roughness is required.

The CNC Cylindrical Grinding Machine significantly improves production efficiency by optimizing grinding parameters and automatic control. On the one hand, the CNC system can automatically adjust key parameters such as grinding speed and feed rate according to the material, hardness and grinding requirements of the workpiece to ensure that the grinding process is both efficient and stable. On the other hand, the automatic control function enables the CNC Cylindrical Grinding Machine to operate continuously, reducing manual intervention and downtime, thereby further improving production efficiency. In addition, CNC Cylindrical Grinding Machines also have powerful data processing capabilities, can record and analyze processing data in real time, and provide strong support for production optimization.

Universal cylindrical grinders are known for their versatility. They can grind workpieces of various shapes and sizes and are suitable for a variety of industries. By replacing different grinding wheels and fixtures, universal cylindrical grinders can easily cope with various grinding needs from simple cylinders to complex surfaces. In addition, universal cylindrical grinders also have strong adaptability and can handle workpieces of different materials, hardness and heat treatment states, providing a wide range of processing options for the manufacturing industry.

With the development of artificial intelligence and machine learning technology, CNC Cylindrical Grinding Machines are gradually developing in the direction of automation and intelligence. Modern CNC Cylindrical Grinding Machines not only have the ability to automatically adjust and optimize the processing process, but also can continuously optimize grinding parameters and processing strategies by learning and analyzing processing data. This intelligent capability makes CNC Cylindrical Grinding Machines more flexible and efficient in dealing with complex processing tasks. At the same time, intelligent technology also reduces the skill requirements for operators, allowing more people to easily master and use CNC Cylindrical Grinding Machines for high-precision processing.