In the field of precision machining, grinding machines are key equipment. For manufacturers seeking high-precision surface treatments, choosing the right type of grinder is crucial.

Content

- 1 I. Cylindrical Grinding Machines: Experts in Precision External and Internal Grinding

- 2 II. Surface Grinding Machines: Pursuing Ultimate Flatness

- 3 III. Cylindrical Grinding Machines vs. Surface Grinding Machines: A Comparative Analysis of Core Characteristics

- 4 IV. Cylindrical Grinding Machine Selection Considerations

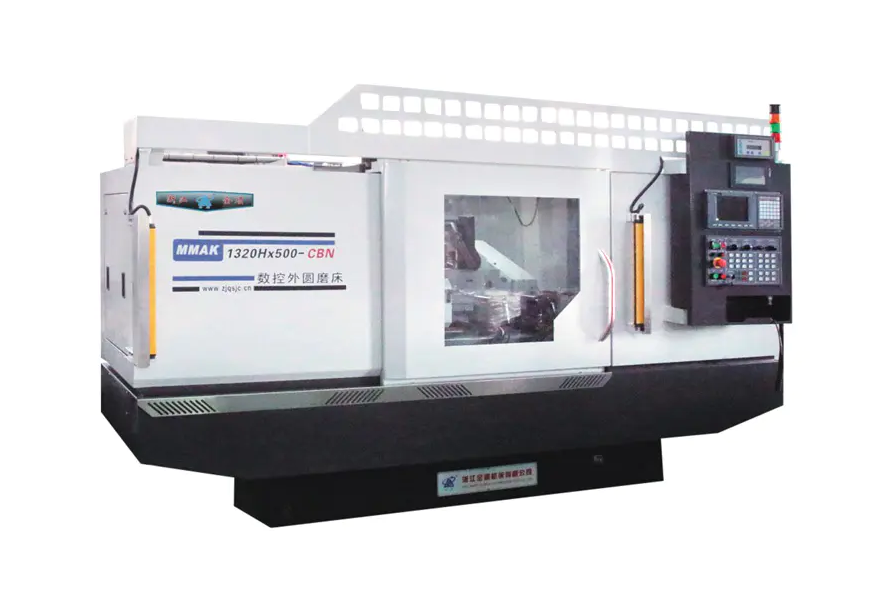

I. Cylindrical Grinding Machines: Experts in Precision External and Internal Grinding

Cylindrical grinders are high-precision machine tools specifically designed for machining the external diameter, internal diameter, and end faces of workpieces. They are ideal for mass production of high-precision shaft and sleeve parts.

Key Features and Advantages of Cylindrical Grinding Machines:

- High Precision Roundness and Concentricity: Utilizing a combination of high-speed grinding wheel rotation and slow workpiece rotation, cylindrical grinders ensure extremely high roundness and concentricity in the machined workpieces, essential for many precision bearings, spindles, and hydraulic components.

- Versatility: Modern CNC cylindrical grinders can perform not only external grinding, but many models can also achieve composite machining such as internal grinding and end face grinding by changing fixtures and grinding wheels.

- Application Scenarios: Primarily used for grinding cylindrical parts requiring precise dimensions and geometric tolerances, such as automotive components (e.g., camshafts, crankshafts), aerospace components, precision machine tool spindles, hydraulic components, and mold parts.

II. Surface Grinding Machines: Pursuing Ultimate Flatness

Surface grinding machines are used to machine flat surfaces (including horizontal, vertical, or inclined planes) of workpieces. They primarily use a grinding wheel to cut the workpiece surface to achieve extremely high surface finish and flatness.

Main Features and Advantages of Surface Grinding Machines:

- Excellent Flatness: Surface grinding machines excel in material removal and achieving extremely high flatness, crucial for parts requiring smooth contact surfaces and precise fits.

- High Surface Finish: The machined workpiece surface has extremely low roughness and high appearance quality.

- Application Scenarios: Widely used in machining mold cavities, precision guideways, measuring tools, machine tool tables, and various parts requiring strict planar fits.

III. Cylindrical Grinding Machines vs. Surface Grinding Machines: A Comparative Analysis of Core Characteristics

The answer to the question, "Which is better, a cylindrical grinding machine or a surface grinding machine?" is not absolute, but depends on your specific grinding task. Below is a detailed comparison of their core characteristics:

1. Main Machining Objects

- Cylindrical Grinding Machine: Focused on machining cylindrical parts, such as various shafts, pins, sleeves, etc. It is a key piece of equipment for achieving workpiece rotational symmetry.

- Surface Grinding Machine: Focused on machining the flat surfaces of various block and plate-shaped parts to obtain extremely high flatness.

2. Main Machining Objectives

- Cylindrical Grinding Machine: The core objective is to pursue high precision in roundness, concentricity (i.e., the accuracy of the alignment between the axis and the outer circle), and cylindricity error. These are indispensable indicators for precision transmission and mating parts.

- Surface Grinding Machine: The core objective is to pursue ultimate flatness error and surface finish to obtain smooth, precise mating surfaces.

3. Key Technical Indicators

- Cylindrical Grinding Machine: Key performance indicators for this equipment include radial runout and cylindricity error.

- Surface Grinding Machine: Key performance indicators for this equipment include flatness error and final surface roughness.

4. Suitable for Mass Production

- Cylindrical Grinding Machine: Ideal for mass production of cylindrical grinding shaft parts requiring precise dimensions and geometric tolerances, offering high efficiency and consistency.

- Surface Grinding Machine: Ideal for mass processing of various parts with high requirements for planar fit, offering high efficiency in planar machining.

If you primarily produce or process cylindrical parts, then choosing a cylindrical grinder is undoubtedly the better solution.

If you primarily process surfaces requiring extreme flatness, then choosing a surface grinding machine is the most efficient and economical solution.

IV. Cylindrical Grinding Machine Selection Considerations

When deciding to purchase a cylindrical grinding machine, in addition to considering the brand and price, you should also pay attention to the following core factors:

- Grinding Range: The center distance and maximum grinding diameter of the machine determine the range of workpiece sizes it can process.

- Automation Level: CNC cylindrical grinders offer a higher level of automation and better machining consistency than traditional manual cylindrical grinders.

- Grinding Wheel Selection: Choosing a grinding wheel suitable for the workpiece material (such as brown fused alumina, white fused alumina, or CBN superhard abrasive) is crucial to achieving the optimal performance of the cylindrical grinder.

- Accuracy Grade: The repeatability and minimum feed rate of the equipment directly affect the final accuracy of the cylindrical grinding.

Whether choosing a cylindrical grinder or a surface grinder, the core consideration should be the actual machining requirements, combined with technical parameters, accuracy requirements, and budget, to select the most suitable grinding equipment for your needs.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体