Crankshaft grinders play a vital role in precision machining. Professionals in the automotive, shipbuilding, and heavy machinery industries are no strangers to this high-performance machine. The crankshaft is the heart of the engine, and its precision directly determines its performance and lifespan. Crankshaft grinders are crucial for ensuring that this core component meets the highest precision requirements.

Content

Core Use of Crankshaft Grinders: Precision Grinding of Crankshafts and Connecting Rod Journals

The core function of a crankshaft grinder is to grind the main and connecting rod journals on the engine crankshaft. These journals must exhibit extremely high dimensional accuracy, geometric precision (such as roundness and cylindricity), and surface finish to ensure a perfect fit with the bearings during high-speed operation, reducing friction and improving engine efficiency and reliability.

- High-precision machining: Crankshaft grinders can achieve crankshaft journal tolerances down to micrometers, a level of precision difficult to achieve with conventional lathes or milling machines.

- Guaranteed Geometric Shape: It accurately corrects deviations in journal roundness, straightness, and taper, ensuring good crankshaft dynamic balance and reducing engine vibration.

- Optimized Surface Quality: The high surface finish after grinding effectively extends bearing life and reduces friction loss.

Applications and Importance of Crankshaft Grinders

Crankshaft grinders are widely used and are indispensable in all industries involved in the manufacture of internal combustion engines, compressors, and reciprocating machinery:

- Automotive Manufacturing: Whether it is gasoline, diesel, or new energy vehicle engines, the machining of their core crankshafts relies on crankshaft grinders.

- Marine and Aviation: The crankshafts of large ship engines and aircraft piston engines are larger in size, requiring higher grinding stability and precision.

- Construction Machinery: Diesel engines in heavy machinery such as excavators and bulldozers also require high-quality crankshafts to withstand the heavy workload.

- Professional Repair: In the engine repair and remanufacturing industry, crankshaft grinders are used to repair worn or damaged crankshaft journals, restoring them to standard or corrected dimensions.

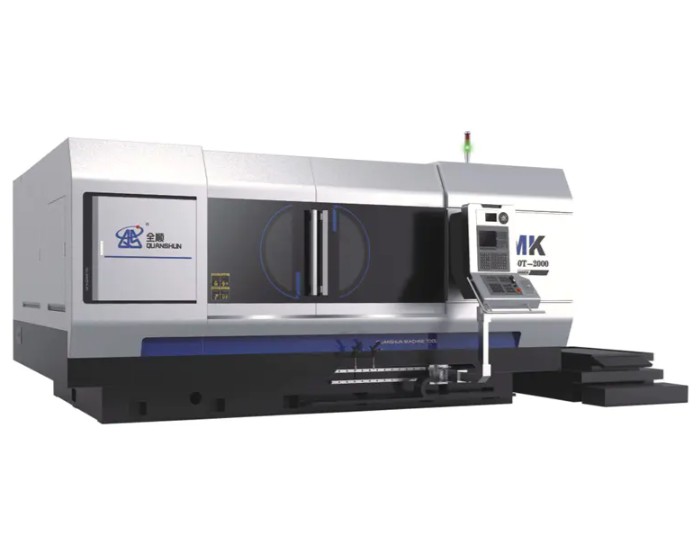

Modern crankshaft grinders typically utilize CNC technology, enabling automated, efficient, and highly flexible grinding processes. They are not only a critical step in the crankshaft machining process but also the cornerstone for ensuring the high-performance operation of the entire mechanical system. Choosing a high-quality crankshaft grinder means higher machining efficiency, more stable product quality, and stronger market competitiveness.

If you're looking for solutions to improve crankshaft and journal machining accuracy, understanding the latest technologies and models of CNC crankshaft grinders is an important first step.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体