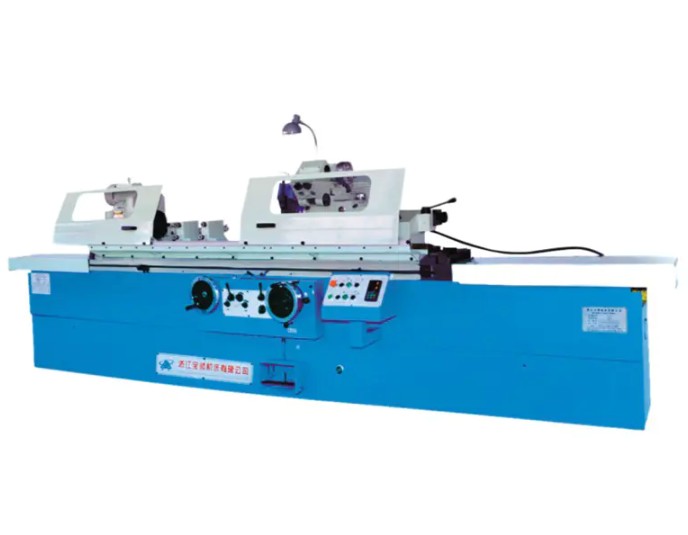

A Conventional Grinding Machine, often referred to as a grinder, is a machine tool that uses abrasive tools to cut workpiece surfaces. Its primary function is to remove material through the grinding process to achieve highly precise dimensions, smooth surfaces, and specific geometric shapes. Conventional Grinding Machines are widely used in industrial production and are indispensable equipment in the field of mechanical processing.

Content

Operating Principle and Types of Conventional Grinding Machines

The operating principle of a Conventional Grinding Machine is primarily to use a high-speed rotating grinding wheel (grinding tool) in contact with the workpiece surface, using the countless tiny hard abrasive particles on the grinding wheel to cut the workpiece. Unlike traditional turning and milling, grinding is a precision machining method that can achieve extremely high machining accuracy and surface quality.

Based on the grinding method and structural characteristics, Conventional Grinding Machines can be divided into several types to meet the machining requirements of different workpieces:

- External cylindrical grinders: Used for grinding the external surfaces of cylindrical and conical workpieces.

- Internal cylindrical grinders: Used for grinding the internal surfaces of workpieces with holes.

- Surface grinders: Used for grinding flat or shaped surfaces.

- Tool grinders: Primarily used for grinding cutting tools such as drills and milling cutters.

- Universal grinders: Combining multiple functions, they can be used for grinding internal and external cylindrical, flat, and conical surfaces.

The Key Role of Grinding Machines and Related Applications

Conventional grinding machines play a vital role in modern manufacturing. They are capable of machining high-hardness materials such as hardened steel and carbide, which are difficult to achieve with other cutting methods. Precision grinding significantly improves the dimensional accuracy and surface finish of parts, thereby ensuring the performance and reliability of the final product. For example, in industries such as automotive, aerospace, and mold manufacturing, many critical components (such as bearings, gears, and crankshafts) require precision machining using grinding machines.

The machining accuracy of a grinding machine depends on multiple factors, including the rigidity of the machine itself, the accuracy of the spindle, and the operator's experience. To improve machining efficiency and precision, modern grinding machines are constantly evolving, for example, by incorporating CNC technology to enable more automated and controllable machining processes.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体