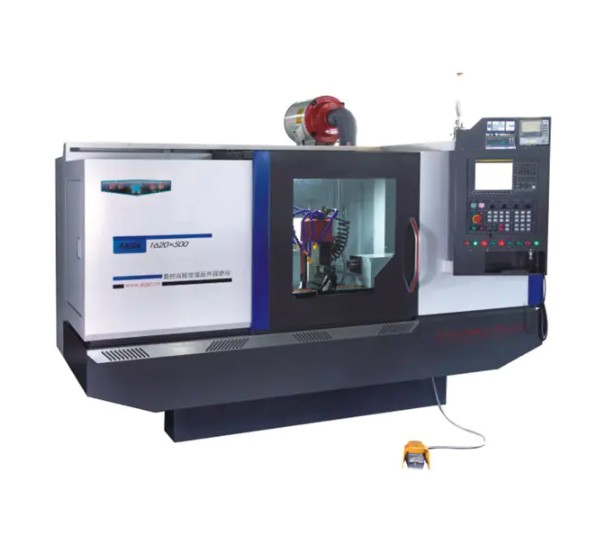

A CNC Cylindrical Grinding Machine is a high-precision, automated metal-cutting machine. As a core piece of equipment in the precision grinding field, it is primarily used for precision grinding of cylindrical, conical, and stepped surfaces on workpieces. Fully automated through a computer numerical control (CNC) system, it combines a high-speed rotating grinding wheel with precise feed motion to grind workpiece surfaces to extremely high dimensional accuracy, form accuracy, and surface quality. It is widely used in industries requiring stringent machining precision, such as automotive manufacturing, aerospace, precision bearings, hydraulic components, and molds, and is a key piece of equipment for ultra-precision machining.

I. Core Components of a CNC External Cylindrical Grinding Machine

The structure of a CNC external cylindrical grinding machine is complex and precise, with core components including the following:

1. Basic Structure

The machine bed: Serving as the foundational support, it requires extremely high rigidity and stability. It is typically constructed of high-strength cast iron or granite, and undergoes aging treatment to eliminate internal stresses and prevent deformation that could affect accuracy during machining. The bed bed's vibration resistance and thermal stability directly determine the machine's long-term machining accuracy.

Worktable: It consists of a longitudinal worktable (which moves the workpiece axially) and a transverse worktable (which moves the grinding wheel head radially). A servo motor drives a ball screw for precise feed, with a feed resolution of up to 0.1μm, meeting micro-feed requirements.

2. Grinding System

Grinding Wheel Head: This is the core component that houses the grinding wheel. The grinding wheel is driven by a spindle at high speed (typically 1000-6000 rpm). The spindle utilizes high-precision hydrostatic bearings, ceramic bearings, or an electric spindle to ensure rotational accuracy (radial runout ≤ 0.001mm) and stability.

Grinding Wheel Type: Depending on the workpiece material (steel, cast iron, ceramic, carbide, etc.) and machining requirements, various grinding wheels can be used, including alumina, silicon carbide, cubic boron nitride (CBN), and diamond. Grit sizes range from coarse grinding (e.g., 36#) to fine grinding (e.g., 2000#). CBN wheels are the preferred choice for machining hard and brittle materials due to their high hardness and wear resistance.

3. CNC System

Core control unit supports G-code programming, a graphical user interface, and parameterized settings.

Functions: Enables multi-axis linkage control (e.g., longitudinal, transverse, and wheel dressing axes), automatic feed adjustment, machining process simulation, and intelligent fault diagnosis, significantly reducing manual operation complexity and serving as the "brain" of machine automation.

4. Workholding and Positioning System

Center: Used for positioning long shafts. The headstock and tailstock coordinate to ensure the accuracy of the workpiece's rotational axis (e.g., roundness error ≤ 0.001mm).

Chuck/Fixture: Suitable for short or irregularly shaped workpieces. Commonly used are three-jaw or four-jaw chucks or custom fixtures. They ensure secure and concentric workpiece clamping, minimizing clamping errors.

Stand/Stand: For slender shafts (aspect ratio > 10), these devices provide auxiliary support to prevent workpiece bending and deformation under grinding forces. They are essential for slender shaft machining.

5. Auxiliary Systems

Cooling System: A spray of cutting fluid (emulsion or oil-based coolant) lowers the grinding zone temperature, minimizes thermal deformation of the workpiece, and flushes away grinding chips to prevent grinding wheel clogging. Some high-end equipment is equipped with a precision cutting fluid filtration system (with an accuracy of 5-20μm) and an oil temperature control system to ensure a stable machining environment.

Grinding Wheel Dressing Device: Automatically dresses the grinding wheel shape (e.g., outer diameter, taper) and cutting edge to ensure grinding accuracy. Commonly used are diamond pen dressers or CNC grinding wheel dressers. These devices support online, real-time dressing to improve batch processing consistency.

II. Working Principle of a CNC Cylindrical Grinding Machine

The machining process of a CNC cylindrical grinding machine is based on the coordinated motion of "high-speed grinding wheel cutting" and "low-speed workpiece feed." It integrates the core principles of CNC technology and grinding processes. The specific process is as follows:

Workpiece Clamping: The workpiece is secured to the worktable using a center, chuck, or fixture to ensure positioning accuracy and minimize datum error.

Parameter Setting: Processing parameters, including grinding diameter, length, feed rate, grinding wheel speed, and cutting fluid flow rate, are entered through the CNC system, or pre-set machining programs are called up. Both offline programming and online modification are supported.

Grinding Process: The grinding wheel rotates at high speed along the spindle (cutting motion), while the workpiece rotates along the worktable at low speed (circular feed). The longitudinal worktable moves the workpiece axially (longitudinal feed), while the transverse worktable drives the grinding wheel carriage radially (engagement), achieving layer-by-layer grinding of the external cylindrical surface.

The CNC system monitors parameters such as grinding force and temperature in real time, automatically adjusting the feed rate through closed-loop control to avoid overload and precision deviations, ensuring stable processing.

Dressing and Inspection: The grinding wheel dressing device automatically dresses the grinding wheel during or after processing. Some machines integrate online measurement systems (such as laser diameter gauges and contact probes) to provide real-time feedback on dimensional errors and automatically compensate for them, achieving high-precision closed-loop processing.

III. Core Advantages of CNC Cylindrical Grinders

Compared to traditional manual or semi-automatic cylindrical grinders, CNC cylindrical grinders offer the following advantages:

1. High Precision and Stability

Dimensional Accuracy: Workpiece diameter tolerances can be controlled within a range of ±0.001-±0.005mm, meeting the requirements of precision part processing.

Form Accuracy: Roundness ≤ 0.0005mm, Cylindricity ≤ 0.001mm/m, and surface roughness up to Ra 0.025μm (mirror finish), meeting ultra-precision machining standards.

Long-Term Stability: Closed-loop servo control, thermal error compensation technology, and precision-retention design ensure batch processing consistency (CPK value ≥ 1.67), meeting the mass precision manufacturing requirements of industries such as automotive and aviation.

2. Automation and High Efficiency

Unmanned Operation Support: Integrated automatic loading and unloading systems (with robots or conveyor belts), automatic grinding wheel changing, and automatic dressing functions reduce manual intervention and enable flexible automated production.

Improved Processing Efficiency: Compared to traditional equipment, batch processing efficiency is increased by 30%-50%, programming time for complex workpieces is reduced by over 60%, and auxiliary time is reduced by process centralization.

3. Flexibility and Adaptability

Complicated Shape Processing: Multi-axis linkage enables single-clamping machining of stepped shafts, tapered surfaces, arc-shaped surfaces, and other special-shaped external circumferences, reducing errors from multiple clampings.

Multi-Material Machining: Stable grinding is possible for materials ranging from ordinary carbon steel and alloy steel to high-hardness materials (such as hardened steel HRC60+, ceramics, composites, titanium alloys, and high-temperature alloys), meeting the machining needs of difficult-to-machine materials.

4. Intelligence and Operability

Intelligent Features: Load monitoring, tool life warnings, machining process simulation, remote diagnostics, and maintenance simplify maintenance and reduce downtime.

User-Friendly Interface: Graphical programming (no complex G-code required) and parameterized settings allow operators to take up the job after a short training period, lowering the technical requirements.

IV. Main Applications of CNC Cylindrical Grinding Machines

Due to their high precision, CNC cylindrical grinding machines have become core equipment in the precision manufacturing industry. Typical applications include:

Automotive Industry: Grinding engine crankshafts, camshafts, drive shafts, hydraulic piston rods, etc. requires a roundness of ≤0.002mm and a surface roughness of Ra 0.4μm or less, meeting the high reliability requirements of automotive precision components.

Aerospace: Machining aircraft engine turbine shafts, landing gear piston rods, precision bolts, etc. requires grinding high-temperature-resistant, high-strength materials (such as titanium alloys and high-temperature alloys) to ensure the stability of aerospace parts under extreme operating conditions.

Precision Bearings: Cylindrical grinding of bearing inner and outer rings requires dimensional tolerances of ±0.001mm and cylindricity of ≤0.0005mm. This is a key process in high-precision bearing manufacturing.

Hydraulic and pneumatic components: Hydraulic cylinders, piston rods, valve cores, etc. must maintain a surface roughness of Ra 0.1μm or less to reduce leakage and wear, thereby improving the efficiency and life of the hydraulic system.

Molds and Tools: Grinding mold guide pins, guide bushings, and precision tool shanks ensures assembly accuracy and service life, supporting the manufacturing of precision molds and high-end tools.

V. Technological Development Trends in CNC Cylindrical Grinding Machines

With the manufacturing industry's ever-increasing demands for precision and efficiency, CNC cylindrical grinding machines are developing in the following directions:

Ultra-high precision: Through nanometer-level feed systems (resolution ≤ 1nm) and constant temperature and humidity machining environment control (ambient temperature fluctuation ≤ ±0.5°C), submicron machining accuracy is achieved to meet the requirements of micro-nano manufacturing.

Intelligent Integration: Integrating the Industrial Internet of Things (IIoT) and AI algorithms enables self-optimization of machining parameters, predictive maintenance, remote monitoring and scheduling, and the creation of intelligent grinding units.

Combined Machining: Integrating internal cylindrical grinding, face grinding, and thread grinding functions enables "one-clamp, multi-faceted machining" of workpieces, reducing clamping errors and increasing process integration rates.

Green Design: Utilizing a low-power servo system, long-lasting cutting fluid filtration technology, and a noise-reducing structure, these features reduce energy consumption and environmental pollution, aligning with the development of green manufacturing.

CNC cylindrical grinding machines are the "guarantee of precision" in modern precision manufacturing, and their technological level directly reflects a country's high-end equipment manufacturing capabilities. Choosing the right CNC cylindrical grinding machine requires considering factors such as the material being machined, the required precision, and production capacity. Furthermore, attention should be paid to the manufacturer's technical support and after-sales service capabilities to fully leverage their core value in precision machining.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体