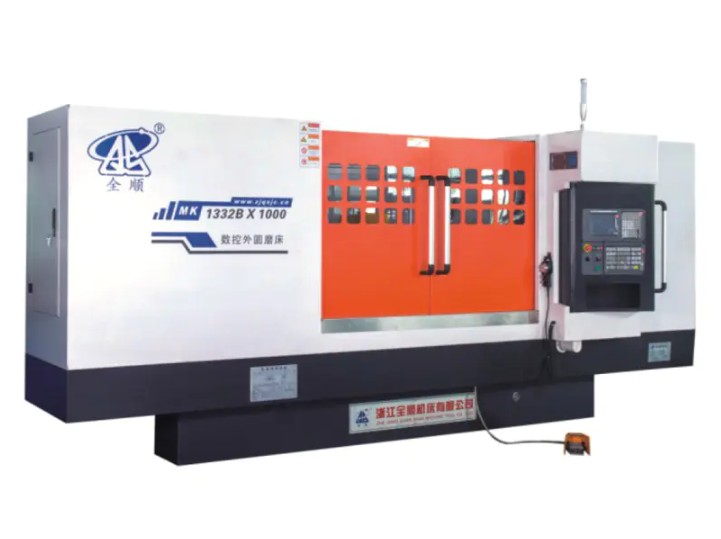

A CNC cylindrical grinder is a high-precision CNC machine tool designed for grinding and finishing the external surfaces of cylindrical or conical workpieces. It utilizes computer numerical control (CNC) technology to precisely control all parameters during the grinding process, enabling efficient, high-quality, and stable mass production.

Content

How a CNC cylindrical grinder works

The core operating principle of a CNC cylindrical grinder is to grind the workpiece using a high-speed rotating grinding wheel. The workpiece rotates under the spindle, while the grinding wheel, controlled by a CNC system, cuts the workpiece surface with exceptional precision. Unlike traditional grinding machines, the entire machining process of a CNC cylindrical grinder is controlled by pre-programmed programs. It can automatically perform complex operations such as grinding wheel dressing, compensation, and multi-axis linkage, significantly improving machining accuracy and automation.

Why choose CNC cylindrical grinders?

In modern manufacturing, the precision requirements for components are becoming increasingly demanding, and traditional grinding machines are no longer able to meet these demands. CNC cylindrical grinders stand out for their unique advantages:

- High Precision and High Efficiency: CNC technology ensures extremely high machining accuracy and repeatability, easily achieving micron-level tolerances. Automated operations reduce manual intervention, significantly improving production efficiency.

- Versatility: Modern CNC cylindrical grinders can machine not only standard cylinders but also grind complex shapes such as stepped and tapered shafts. Some advanced models also integrate internal and end grinding functions.

- Stability and Reliability: The CNC system’s precise motion control reduces human error and ensures consistent product quality.

- Wide Application: These machines are widely used in automotive, aerospace, medical devices, precision instruments, and mold industries. They can efficiently process materials such as carbide, stainless steel, and ceramics.

How to choose the right CNC cylindrical grinder?

- Processing Requirements: Consider the workpiece size, material, and tolerance requirements to select proper specifications, spindle power, and rigidity.

- Automation Level: Decide whether additional features like automatic loading/unloading and on-machine measurement are necessary.

- Brand and Service: A reputable manufacturer with strong after-sales service and technical support ensures stable long-term operation.

CNC cylindrical grinders are an ideal choice for precision manufacturing and productivity improvement. With high precision, efficiency, and automation, they have become indispensable equipment in modern industry.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体