In the complex chain of modern industrial manufacturing, Crankshaft grinding machines play a crucial role, especially in the machining of high-precision, high-performance engine and mechanical parts.|

Content

I. Precision Machining of Core Components: Crankshaft Main Journals and Connecting Rod Journals

The primary application and core function of crankshaft grinding machines is to achieve ultra-precision grinding of the main journals and connecting rod journals on the crankshaft.

Achieving High-Precision Dimensional Tolerances: During high-speed operation, engine crankshafts require extremely small clearances between the journals and bearings to ensure lubrication and stability. Crankshaft grinding machines can control the diameter tolerances, roundness, and cylindricity of the journals at the micrometer level, which is crucial for ensuring engine performance and lifespan.

Optimizing Surface Roughness: The surface roughness (e.g., Ra value) of the ground journals is extremely low, which effectively reduces friction and wear during operation, improving fuel efficiency and engine reliability.

II. Meeting Diverse Crankshaft Machining Needs

The applications of Crankshaft grinding machines are not limited to automotive engines. Its versatility and high precision make it widely used in multiple industries:

Automotive Industry

Undoubtedly, this is the largest application area for crankshaft grinding machines. From economy cars to high-performance sports cars to heavy-duty trucks, the manufacturing of crankshafts for all internal combustion engines relies on crankshaft grinding.

Aerospace Industry

Aero engines have even higher requirements for the precision and reliability of components. Crankshaft grinding machines are used to process crankshafts for aero-engine piston engines, ensuring their stable operation under extreme conditions.

Marine and Large Machinery

Used to process heavy-duty crankshafts in large marine diesel engines, generator sets, and construction machinery. These crankshafts are large and heavy, placing higher demands on the stability and rigidity of the grinding machine.

Compressors and Pumps

Used to process special crankshafts in various air compressors, refrigeration compressors, and high-pressure pumps to ensure smooth operation and high efficiency of the machinery.

III. Improving Processing Efficiency and Automation Level

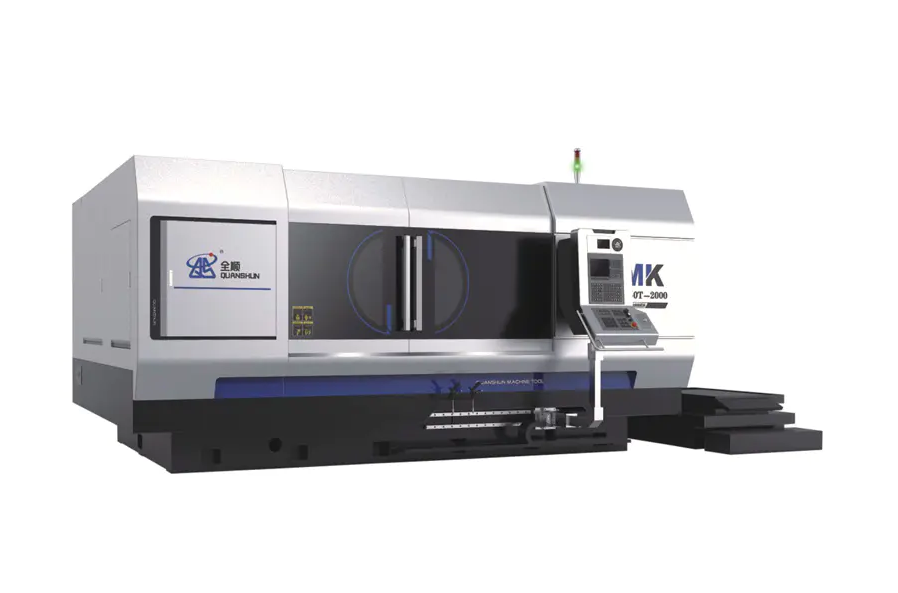

Modern Crankshaft grinding machines are no longer simple grinding tools, but rather a core component of high-efficiency, automated production lines.

Numerical Control and Automation: Modern CNC crankshaft grinding machines can achieve fully automated loading, unloading, measurement, grinding, and compensation, greatly improving production efficiency and product consistency.

Non-Circular Grinding Capability: Some advanced grinding machines possess non-circular grinding capabilities, used to machine special balance blocks or complex geometries on crankshafts to further optimize engine balance and vibration characteristics.

Crankshaft grinding machines are key technological equipment for achieving mass production of high-performance, high-reliability engines. Through ultra-precision machining of crankshaft journals, they ensure the smooth, efficient, and long-lasting operation of engines, making them a "behind-the-scenes hero" of modern machinery manufacturing.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体