In modern precision manufacturing, cylindrical grinding machines play a crucial role. From crankshafts in automobile engines to high-precision bearings in aerospace, these high-precision machine tools are indispensable.

Content

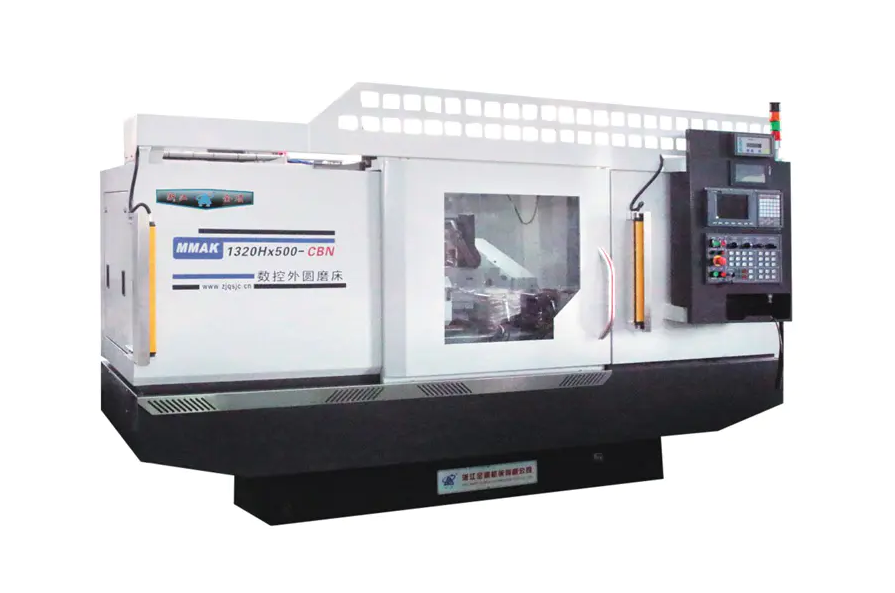

What is a cylindrical grinding machine?

Cylindrical grinding machines are primarily used for grinding the outer cylindrical surfaces, outer conical surfaces, and shoulder end faces of workpieces. Simply put, its working principle involves rotating the workpiece around a central axis while a high-speed rotating grinding wheel performs micro-cuts on the workpiece surface, achieving extremely high dimensional accuracy and surface finish.

Core Applications of Cylindrical Grinding Machines

The indispensable role of cylindrical grinding machines in machining workshops is primarily due to the following core functions:

Achieving Ultra-Precision Dimensional Control

Compared to turning, cylindrical grinding machines can control the diameter tolerance of parts at the micrometer level. This is crucial for mechanical parts requiring precise fit.

Improving Surface Roughness

Grinding processes can significantly reduce the surface roughness of parts, achieving a mirror-like finish. This is of great significance for reducing friction and wear during mechanical operation.

Machining High-Hardness Materials

Traditional cutting tools struggle to effectively cut hardened or extremely hard alloys. Cylindrical grinding machines, however, utilize diamond or silicon carbide grinding wheels to easily handle these high-hardness workpieces.

Main Classifications of Cylindrical Grinding Machines

Based on their level of automation and structure, cylindrical grinding machines are generally classified as follows:

- Universal Cylindrical Grinding Machines: Equipped with internal grinding attachments, they can grind both external diameters and internal holes, offering high flexibility and suitability for single-piece or small-batch production.

- CNC Cylindrical Grinding Machines: Controlled by computer programming, they can automatically grind multi-step axes, offering higher processing efficiency and consistency, making them the preferred choice for large-scale production.

- Ordinary Cylindrical Grinding Machines: Primarily operated manually, suitable for machining relatively simple parts.

Wide Range of Applications

Due to their superior machining characteristics, cylindrical grinding machines are widely used in several cutting-edge manufacturing fields:

- Automotive Industry: Mainly used for machining core power components such as engine camshafts, crankshafts, and drive shafts, ensuring stability under high-speed operation.

- Machine Tool Manufacturing: Responsible for the final machining of precision spindles, ball screws, and guide pillars, crucial for ensuring the precision of machine tools.

- Hydraulics and Pneumatics: Ensures the sealing performance of seals under high-pressure environments through precision grinding of piston rods, valve cores, and hydraulic cylinders.

- Aerospace: Used for processing critical components with extremely high requirements for material hardness and geometric tolerances, such as turbine shafts and high-precision bearing rings.

As a vital component of industrial mother machines, cylindrical grinding machines not only improve the machining accuracy of parts but also drive the manufacturing industry towards intelligence and precision. If you are pursuing extremely high geometric tolerances and surface quality, cylindrical grinding machines are undoubtedly a core guarantee for your production line.

0086-15068518279 (Chinese)/001-5416026691 (English)

0086-15068518279 (Chinese)/001-5416026691 (English)

EN

EN

中文简体

中文简体