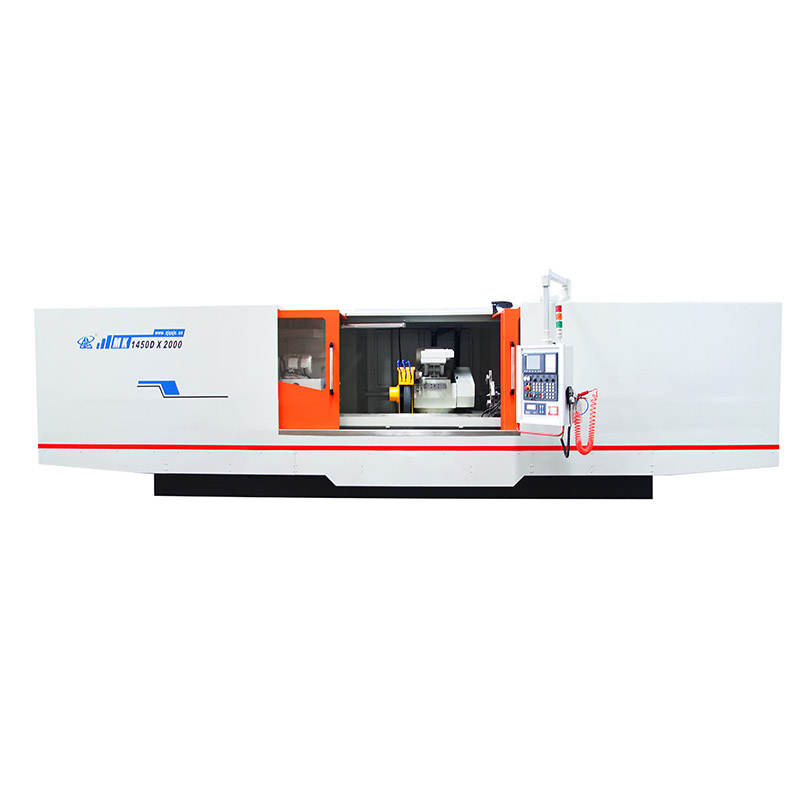

The CNC internal grinder is also one of the high-precis […]

The CNC internal grinder is also one of the high-precision grinder products. The precision grinder product must be able to ensure the stability of the equipment during use, and there should be no shaking during the use of the equipment, so as not to affect the operating accuracy of the equipment. When the CNC grinder is processing precision abrasive tools, the machine tool cannot be deflected or vibrated. Even small vibrations may affect the production effect of the equipment.

There are many reasons for the vibration of the equipment. It may be the quality of the machine itself or the external environment. In short, we must be able to find the cause of the problem in time, and then solve the problem as soon as possible. After we discover the shaking problem of the machine tool, we must first find the problem. It may be that the grinding machine spindle has been used for a long time and it has generated vibration. It may be the bearing or motor inside. It may also be the structure of the machine tool. There is a problem with the assembly. So how do we find the problem?

1. Check the ground level first

As the saying goes, the stability of the building depends on whether the foundation is well laid? The same is true for the use of CNC grinders. After discovering the vibration of the equipment, we must first check whether the ground is stable. If the ground is not stable enough, we must move the equipment. To the ground more suitable for production. If the cause of the vibration is not the ground but the foundation of the equipment itself, then it is more troublesome. We need to adjust the level of the equipment's anchor screws to prevent resonance of the equipment.

2. Space on the ground floor

Too empty the floor will also cause the equipment to shake, and the emptiness of the concrete floor will cause resonance and cause the equipment to shake. How to deal with this situation? We can use terrazzo or floor tiles to solve the problem of vacancy on the ground. We can also buy a few black rubber pads and put the rubber pads under the horizontal floor mats to solve the problem. NS.

3. Processing environment

If the above reasons are not the cause of the shaking of the equipment, then we will check the surrounding environment. If there are too many large equipments around the machine tool, it may cause the shaking of the equipment due to resonance. Precision CNC grinders should not be placed near the same working site, such as punching machines, lathes, and other large-vibrating machine tools, which will easily cause resonance of the grinder. It is best for users to separate these large equipment in the workshop to prevent their mutual influence.

www.china-quanshun.com