Safety technical regulations and safety precautions for […]

Safety technical regulations and safety precautions for tool grinders should allow professionals with electrician operation certificates to install or repair electrical appliances. Check whether the voltage and frequency on the motor nameplate are consistent with the power supply before starting up. The contact pins on the power plug and socket of the machine tool should be fastened and reliable without looseness or non-contact. Do not abuse the wire, do not yank the power cord on the socket, keep the wire away from high temperature, greasy, and sharp edges. When a fault occurs or there is an abnormal sound response, immediately pull the plug, turn off the button switch on the left side of the headstock of the machine tool, and then perform inspection and repair. Do not let the machine tool run without unmanned operation, and it must be shut down and stopped before leaving. When the power is cut off from the outside world, press the red button, otherwise the machine tool will be powered down and run without people.

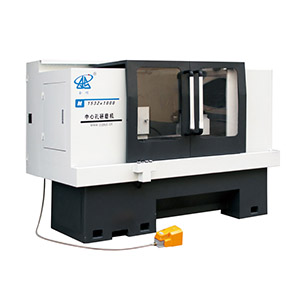

Technical parameters of tool grinder, can grind workpiece maximum turning diameter: 250mm, front and rear * distance: 650mm. Table size: 940×135mm, horizontal movement of the worktable: 230mm Maximum vertical movement of the grinding head 230mm Spindle speed of the grinding head: 2650/3800 5350/7600r/min Motor power of the grinding head: 0.45, 0.6kw Machine size: 1350×1270×1250mm machine tool net weight: 1000kg.

Features of tool grinder, the worktable adopts imported high-precision linear rolling guide, the table is stable, and the operation is light and handy. This machine can match various accessories according to the tool to be ground, and can grind various end mills, end mills, R-type milling cutters, cylindrical milling cutters, three-face milling cutters, single-angle milling cutters, reamers, turning tools , R type. Turning tools, hobbing tools, drills, taps, engraving tools, powerful cutting tools, paper cutters, etc. He type knives. The motor can rotate 360 degrees, and the two sides are equipped with grinding wheels to increase the controllability of tool grinding. When grinding tools of different materials, just rotate the grinding wheel head to start grinding again. There is no need to replace the grinding wheel, which can increase safety and reduce the interaction of grinding wheels. Time for replacement and renovation. Use high-strength FC30 cast iron to maintain mechanical accuracy for a long time.

www.china-quanshun.com