During surface grinding, the workpiece can be installed […]

During surface grinding, the workpiece can be installed on a rectangular worktable with reciprocating linear motion, or on a circular worktable with circular motion. When the grinding wheel peripheral grinding method is adopted, the main shaft of the grinder is arranged horizontally; when the grinding wheel end face grinding method is adopted, the main shaft of the grinding machine is arranged vertically. According to the combination of spindle layout and worktable shape, ordinary surface grinders can be divided into the following four categories:

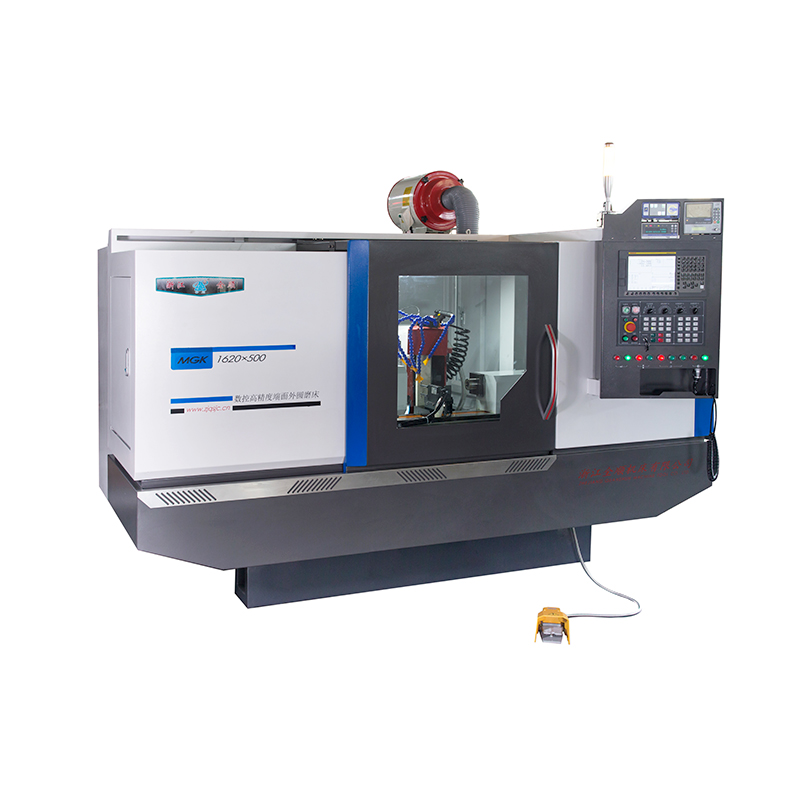

1. Horizontal spindle and moment table surface grinder. In this kind of machine tool, the workpiece is held by a rectangular electromagnetic table. The grinding wheel makes the main rotation movement, the worktable makes longitudinal reciprocating movement, and the grinding wheel carriage makes intermittent vertical cutting movement and lateral feed movement.

2. Vertical axis round table surface grinder. On this machine tool, the grinding wheel makes the main rotation, the round table rotates for circular feed movement, and the grinding wheel holder makes intermittent vertical cutting movement.

3. Vertical axis and rectangular table surface grinder. On this kind of machine tool, the grinding wheel makes the main rotation movement, the rectangular table makes the longitudinal reciprocating movement, and the grinding wheel carriage makes the intermittent vertical cutting movement.

4. Horizontal axis circular table surface grinder. On this kind of machine tool, the grinding wheel makes the main rotating motion, the circular table rotates for the circular feed motion, and the grinding wheel holder makes continuous radial feed motion and intermittent vertical cutting motion. In addition, the center line of rotation of the worktable can be adjusted to an inclined position to facilitate grinding of the conical surface.

Among the above four surface grinders, the surface grinder that uses the end face of the grinding wheel to grind is compared with the surface grinder that uses the rim to grind. Because the diameter of the end face is often larger, it can simultaneously grind the full width and grinding area of the workpiece. Larger, so the productivity is higher. However, when end grinding, the grinding wheel and the workpiece surface are in arc line or surface contact, the contact area is large, the cooling is difficult, and the chips are not easy to remove. Therefore, the processing accuracy and surface roughness are slightly worse.

Compared with the rectangular table surface grinder, the circular table surface grinder has a slightly higher productivity. This is because the circular table has continuous feed and the rectangular table has a loss of commutation time. In addition, the round table is only suitable for grinding the end faces of small parts and large diameter ring parts, and cannot grind long parts, while the rectangular table can easily grind various common parts, including ring parts with a diameter smaller than the width of the rectangular table.